Michael Hillebrand (1952–2025): A Legacy in Weaving

Remembering Michael Hillebrand: Founder, Co-Owner and President of MTL

Michael Hillebrand, founder of MTL and a quiet fixture in the American textile industry, passed away this fall. Michael built something rare: a U.S.-based weaving mill that not only survives, but thrives on complexity, collaboration, and integrity. MTL became a place where innovation and Old World techniques meet everyday, where the looms run just steps from the design studio, and where the work speaks louder than any label. In honor of Michael’s life and legacy, we’re revisiting our 2023 feature on MTL and its design director, Joy McGruther Alaoui, originally published in The Textile Eye No. 18: American Textile Design.

UNMASKING MTL: Patterns of Excellence

Since its inception in 1988, Material Technology & Logistics (MTL), under the leadership of founder Michael Hillebrand, has been redefining the realm of specialized, high-end woven products for both the contract and residential textile markets. Functioning as a niche weaver, MTL’s distinctiveness lies in its ability to craft fabrics that can be found in the collections of the world’s premier fabric houses. Collaborating seamlessly with these design teams, MTL weaves its creativity into the threads of bespoke textiles. The mill’s approach to production closely mirrors that of its European counterparts, as it consistently dyes unique colors and crafts tailor-made warps for its clientele. Nestled in Pennsylvania, this enclave of Old World craftsmanship remarkably bucks the trend of North American imports by exporting its products to numerous western European nations.

A pivotal collaboration over 15 years ago with French heritage weaver Leclercq-LeRoux stands as a cornerstone in MTL’s journey. This partnership brought exceptional epinglé weaving expertise to the US, ensuring the company’s evolution. Anchoring this trajectory is the design director, Joy McGruther Alaoui, who has been an integral part of the company since 1998. Alaoui aims to create luxury textiles that can’t be found anywhere else—a true labor of love.

Did you have special training to design jacquard textiles?

I have a BFA in drawing and an MS in textile design with a concentration in wovens. All of our textile designers graduated from RISD or Jefferson University in textile design. Textile designers that work for weaving mills have a very specific set of talents–we are equal parts artist and engineer. There’s never a single day we’re not learning on the job. In textile design, the learning is permanent and constant.

What advice would you give to your younger self when starting out in the industry?

Play even more. Experiment even more. Take even more design risks. Be bold. Trust your instincts. Not everything you design has to make sense. Strive to design the things no other mill is designing, but never look over your shoulder. I learned early on that color is the most important thing. A mediocre fabric design in a gorgeous and intriguing colorway will get more attention than an exquisite fabric design woven in beige. Color first, always.

Please describe the development process for MTL-designed collections.

We pull together a large group of new original textile designs a few times a year–hundreds of new designs each year. The process is quite organic and intuitive. Our goal is to get our customers excited about the samples we’re showing. Some of the things we show are experimental; some are completely resolved and ready to be purchased on the spot. We try to design a little bit of everything; when we show our collections there’s a fun flea market aspect to it. It’s our customer’s job to find the hidden treasures we’re pulling out of our bag. My personal goal is to have the customer reach across the table because they can’t resist touching the fabrics.

Is there something about your creative process that would surprise people?

We create hundreds of designs each year and nearly all of them are created without doing any revisions at all. Our designers are master visualizers and obsessive perfectionists. The upfront work and forethought that go into creating these types of complex woven textiles is quite impossible to accurately describe. We weave a large portion of our designs on custom warps and don’t have the luxury of doing rounds of revisions to get a design perfected. But when one of our textile designs comes together exactly as we hoped, it’s exhilarating. The entire process is a labor of love.

How would you describe your approach to design?

Our specialty is designing multicolor fabrics that are highly complex structurally. We rarely rely on novelty yarns to create texture or surface interest. Instead, we are constantly creating new, unique weave structures.

Do you consider yourself to have an American design sensibility?

Yes, we’re decidedly American in our aesthetic. When we show our collections to our European clients, they always notice this and comment on it.

Where do you see the future of American design heading?

To exist as an American weaving mill today means being a unicorn. The only thing we’ve ever known is having the bar raised higher and higher each year. The competition we face from overseas is fierce. I see the future of American textile design becoming increasingly custom and even more collaborative than we are today.

How do you incorporate cultural influences into your textile design work in a thoughtful manner?

Research, research, research. Ethnic, indigenous, and historic textiles are endlessly inspiring in their intricacy and richness. When we study these textiles, our goal is to fully understand exactly how they are constructed. Our aim is to honor those weaving methods and techniques by not watering them down and remaining as authentic in our interpretations as we possibly can.

How do you approach color selection and palette creation for your textiles?

Color is what brings a textile design to life. Color creates energy in so many ways. I admire and applaud the fabric editors that take risks with color. From where I sit, I’m convinced 25% of every line should be risky colorways with a distinct point of view. By risky, I don’t necessarily mean shocking. Taking a risk with color could mean going with the soft neutral that has bits of unexpected accent colors. It’s never a mistake to devote lots of time and energy to coloring your fabrics. Trust me, it pays off in the long run.

What inspires your color choices overall?

An important part of my job is to create MTL’s yarn color palettes, and it’s something I take very seriously. We work with a wide variety of clients, and we try to create color palettes that appeal to all of them. Plus, the color palettes of our various yarn styles need to be friendly to each other.

Tell us about some of the challenges faced by MTL.

The number of boxes a fabric needs to tick grows longer each year. It’s rarely just enough for a fabric to be simply beautiful. It must also pass testing for use in public spaces, be highly cleanable, hit an acceptable price point, have a sustainability aspect, be soft and have a supple hand/drape, be aesthetically original, never fade, have some marketing story, be developed at lightning-fast speed, etc. Some days it can honestly feel very discouraging. Our goal has always remained the same: design and weave what no other mill is willing or capable of doing.

What makes the mill special?

I think the decision we made to keep our design studio inside our weaving mill is one of the best decisions we ever made. There’s literally one door between our studio and our looms. Being able to live with the looms and the weavers every day has become vital to our creative process.

Is there something about MTL that you’d like people to understand better?

We are an invisible, wholesale-only manufacturer. None of the fabrics we design or weave have our name on them, and we hope we can continue to exist this way forever into the future. We are experts at textile design and weaving – those are the only two things we want to do.

Tell us about the Weave Lab initiative.

Every custom mill battles against accumulating excess yarn inventory, and it’s the most financially challenging thing we face. MTL weaves with around 2,000 different colors of various yarn and fiber types. Our idea with The Weave Lab was to create unique limited-edition products that are woven out of small leftover quantities of yarn in MTL’s warehouse. It’s a win-win-win situation!

THE FRENCH CONNECTION

in 2005, MTL’s co-owner, Benoit Leclercq, brought his family’s 150-year-old weaving legacy to the company, including an archive of over 80,000 woven samples and artwork, all stored in a specially built archival vault at the mill. This heritage adds a historic dimension to MTL’s American roots. Benoit also brought antique looms and skilled weavers to ensure the continuation of his family’s craft. This partnership bridges the gap between history and innovation, safeguarding a precious tradition.

Tell us about the history of Leclercq-LeRoux.

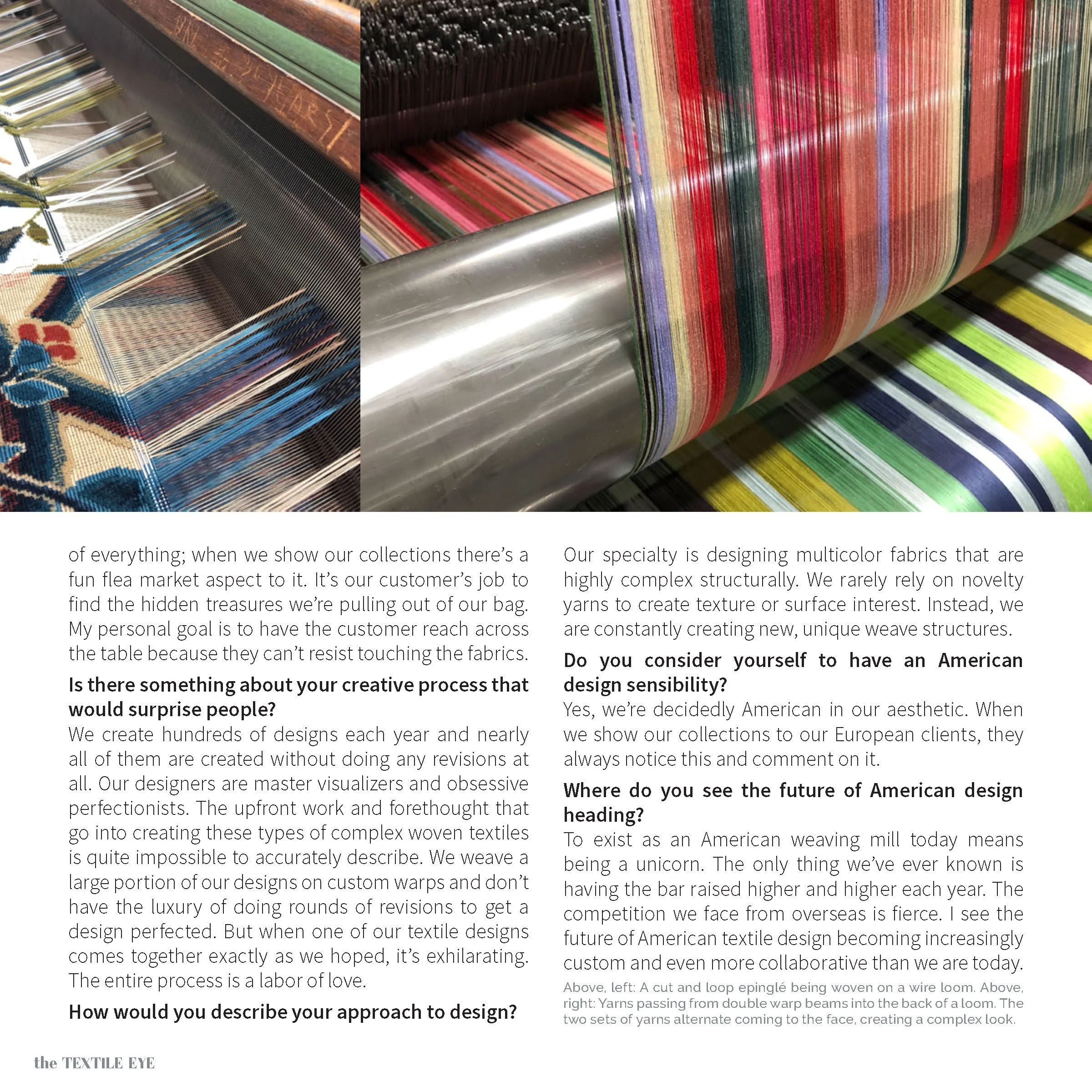

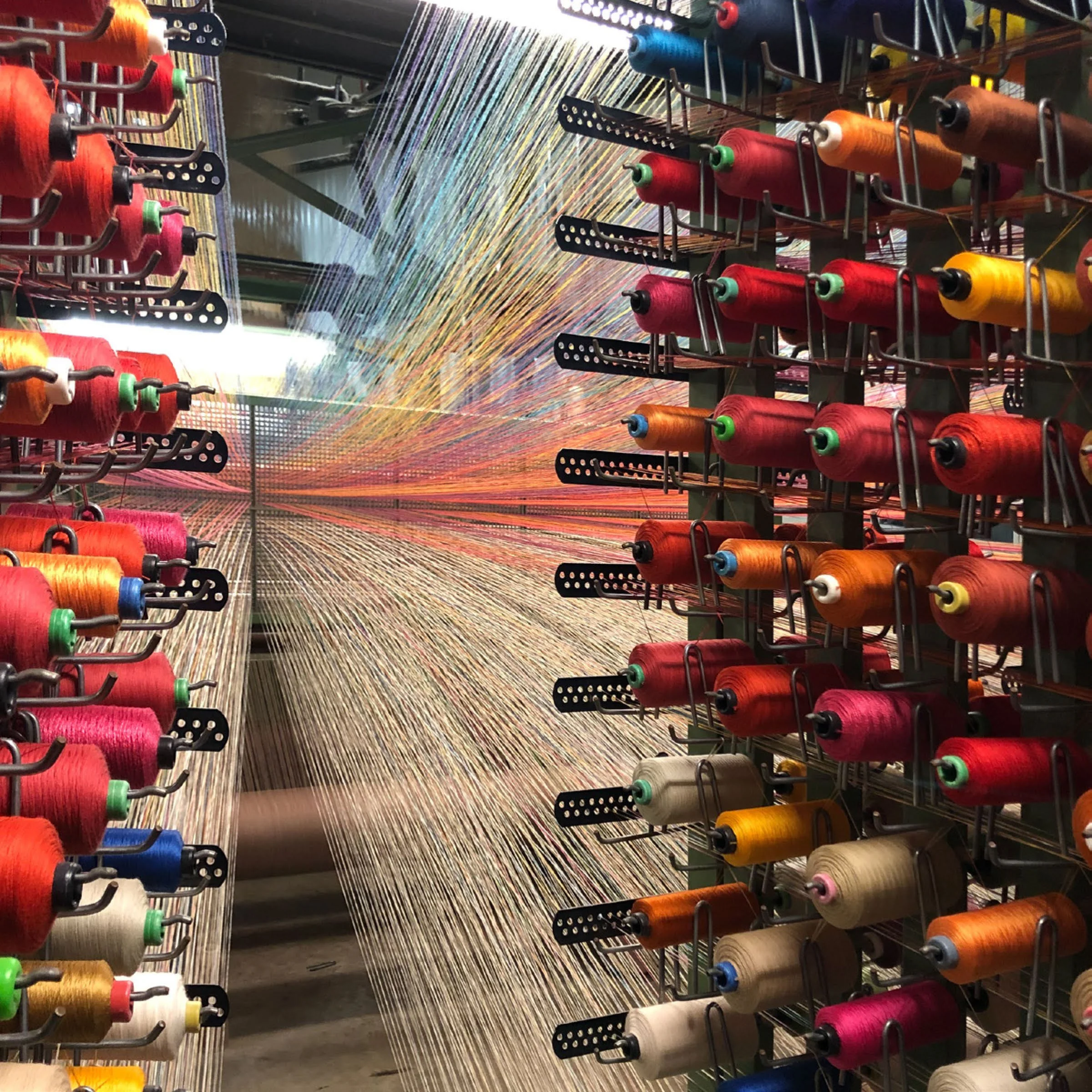

The mill dates back to 1847 and was located in Hem, France. One of their specialties was cut-and-loop pile jacquard velvets woven on wire looms. In 2007, MTL and Leclercq-Leroux consolidated into one weaving mill in Jessup, PA. As part of this transition, a team of French weavers came and lived in Jessup for five years to share their expertise with MTL’s American weavers.

Why is epinglé such a special textile?

True epinglé must be woven on special looms that weave wires into the fabric together with the weft yarns. When the wires are extracted, small tight loops are formed. A specific weave structure is used to permanently trap the loops into the fabric, and the resulting fabric is highly durable. MTL weaves dobby and jacquard all-loop epinglés, and jacquard velvets that incorporate both cut velvet pile and epinglé loop pile in the same fabric.

Epinglé is woven with a creel instead of a warp beam. This means thousands of yarn bobbins are set up behind the loom, and each yarn is fed through independently. It’s labor-intensive, but creates beautiful color variation.